Helicopter Aerial Inspection of High Voltage Installations

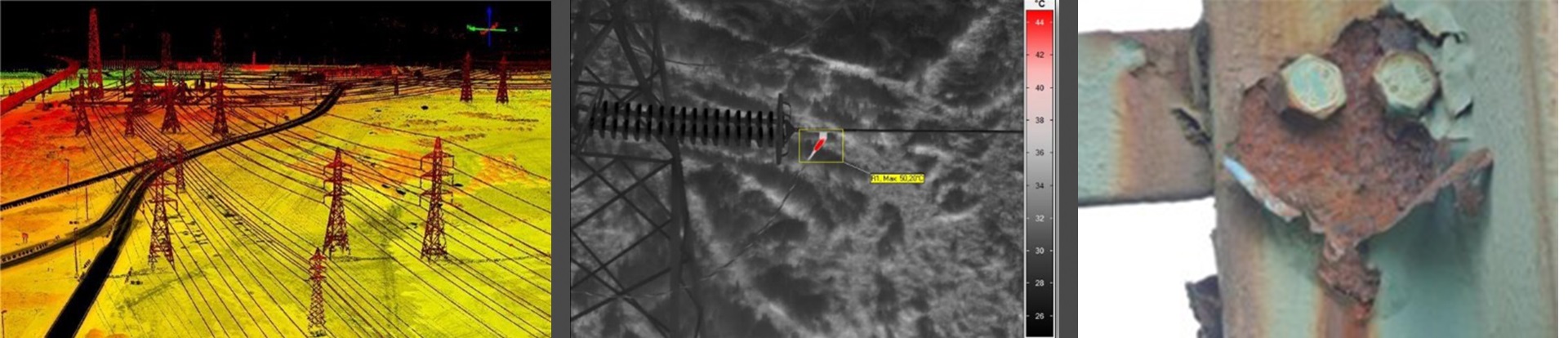

Visual Inspection (4K Video & Photogrammetry)

Visual Inspection (4K Video & Photogrammetry)

Infrared Inspection (Hotspot Detection)

Infrared Inspection (Hotspot Detection)

Ultraviolet Inspection (Corona & Partial Discharges)

Ultraviolet Inspection (Corona & Partial Discharges)

LiDAR Corridor Mapping (Critical Distances Analysis)

LiDAR Corridor Mapping (Critical Distances Analysis)

3D Modelling, Point Cloud Generation & Back Office.

3D Modelling, Point Cloud Generation & Back Office.

The fact that High Line Division S.L. is a Transmission & Distribution Power Lines & Substations maintenance & inspection company, makes the difference, as this is our scope of works since the origin of the Company. With thousand kilometers of Transmission & Distribution lines inspected using helicopters, drones, and land crews, with an exhaustive portfolio of successfully completed projects enable us to provide the best solution for aerial inspection worldwide.

HELICOPTER INSPECTION EQUIPMENT

Trakka SWE 400 Gimbal featuring UHD, 4K Visual, Infrared and Corona sensors).

Trakka SWE 400 Gimbal featuring UHD, 4K Visual, Infrared and Corona sensors).

Infratec Vario CAM HD Infrared Sensor 1024 x 768PX.

Infratec Vario CAM HD Infrared Sensor 1024 x 768PX.

Meteorological Station VAISALA PTU-300 with external probe PTU-307.

Meteorological Station VAISALA PTU-300 with external probe PTU-307.

RIEGL VUX-1 LiDAR Long Range Sensor w/ Applanix IMU.

RIEGL VUX-1 LiDAR Long Range Sensor w/ Applanix IMU.

Onboard SONY Alpha 7 RIV with 300 mm tele objective (and others).

Onboard SONY Alpha 7 RIV with 300 mm tele objective (and others).

Onboard Uvirco Corocam 7, for Corona and Partial Discharges inspection back Up.

Onboard Uvirco Corocam 7, for Corona and Partial Discharges inspection back Up.

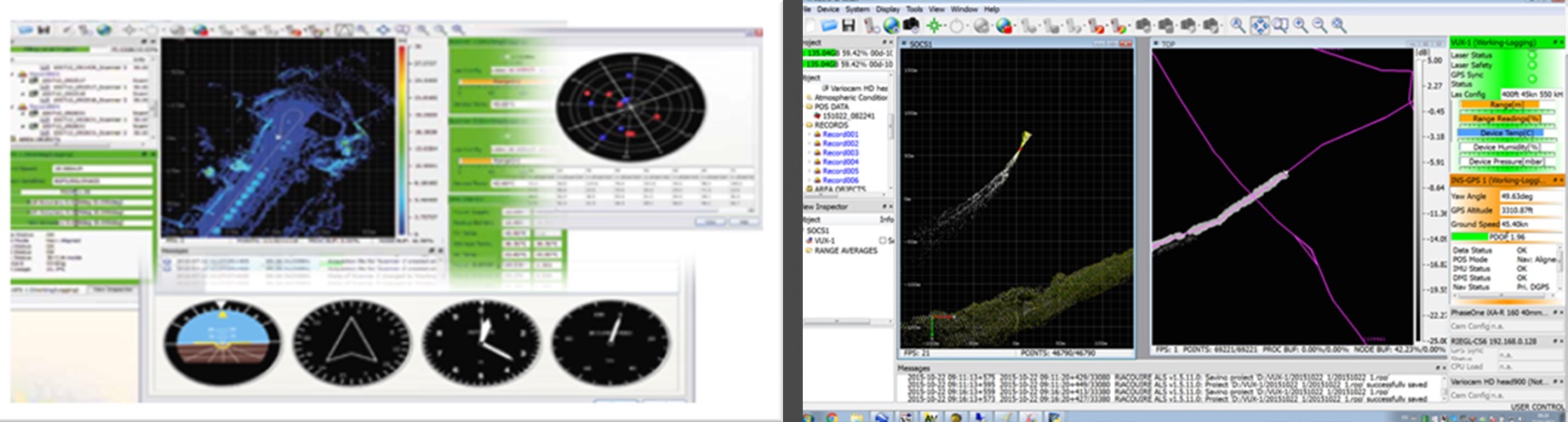

BACK-OFFICE DATA ANALYSIS & REPORTING

Back Office Data Analysis starts with the control and monitoring of the operation at site, then comes the data collection and monitoring the integrity of the data obtained at site. Then comes engineering analysis (back office), quality control, issuance of deliverables and ensures the backup system integrity is correct and recoverable.

Customer requirements identification.

Customer requirements identification.

Flight Operations Planning & On Flight Data Capture monitoring.

Flight Operations Planning & On Flight Data Capture monitoring.

Data Collection & Inspection Obtained Data.

Data Collection & Inspection Obtained Data.

Back Office Analysis.

Back Office Analysis.

Deliverables Issuance, Backup & Traceability Service.

Deliverables Issuance, Backup & Traceability Service.

Quality Control & Customer Survey.

Quality Control & Customer Survey.

Customer Requirements Identification is the first stage when we identify customer requirements, standards and specific project needs and expectations. Here is where we establish the general project guidelines, standards, inspection parameters & general processes take place.

Flight Operations & On Flight Data Capture monitoring, this part of the project, starts with operations planning, allocation of the necessary resources and monitoring the external geographic & environmental conditions governs the flights operation, crew composition and logistical support. Once environmental, legal (permits & authorizations), logistical and operational team is ready to start the operations. Flight techniques are determined according to project requirements and operationally monitored from our Live Console.

Data Collection & Inspection Obtained Data, Crew & Office personnel monitor the data collection, its suitability and integrity. We confirm software disposition, the interaction with inertial & geo-positioning systems works correct and proper process takes place preparing all data for back-office analysis.

Engineering department double check data related to aerial inspection or point cloud classification are correct, ensures its integrity and backup for raw data obtained.

Data Analysis, Assessment & Software Solutions, our engineering department takes into consideration customer requirement, legal standards, and inspection manual to align inspection criteria and determine anomaly levels and its codification. Software to be used, parameters and setting to run the workflow routines takes place. Point cloud classification, hypothesis criteria established (wind, temperature, vegetation critical distances, etc.).